Under bus rust busting begins. Steph jumps in with the wire wheel.

I’m not particularly fond of – or good at – metal fabbing things. I’m a wood guy for sure, despite the rally/car-guy thing. So I was a bit disheartened when Steph and I discovered that one of the coach beams, underneath the bus body and just above the truck frame rail, was really, really rotted out.

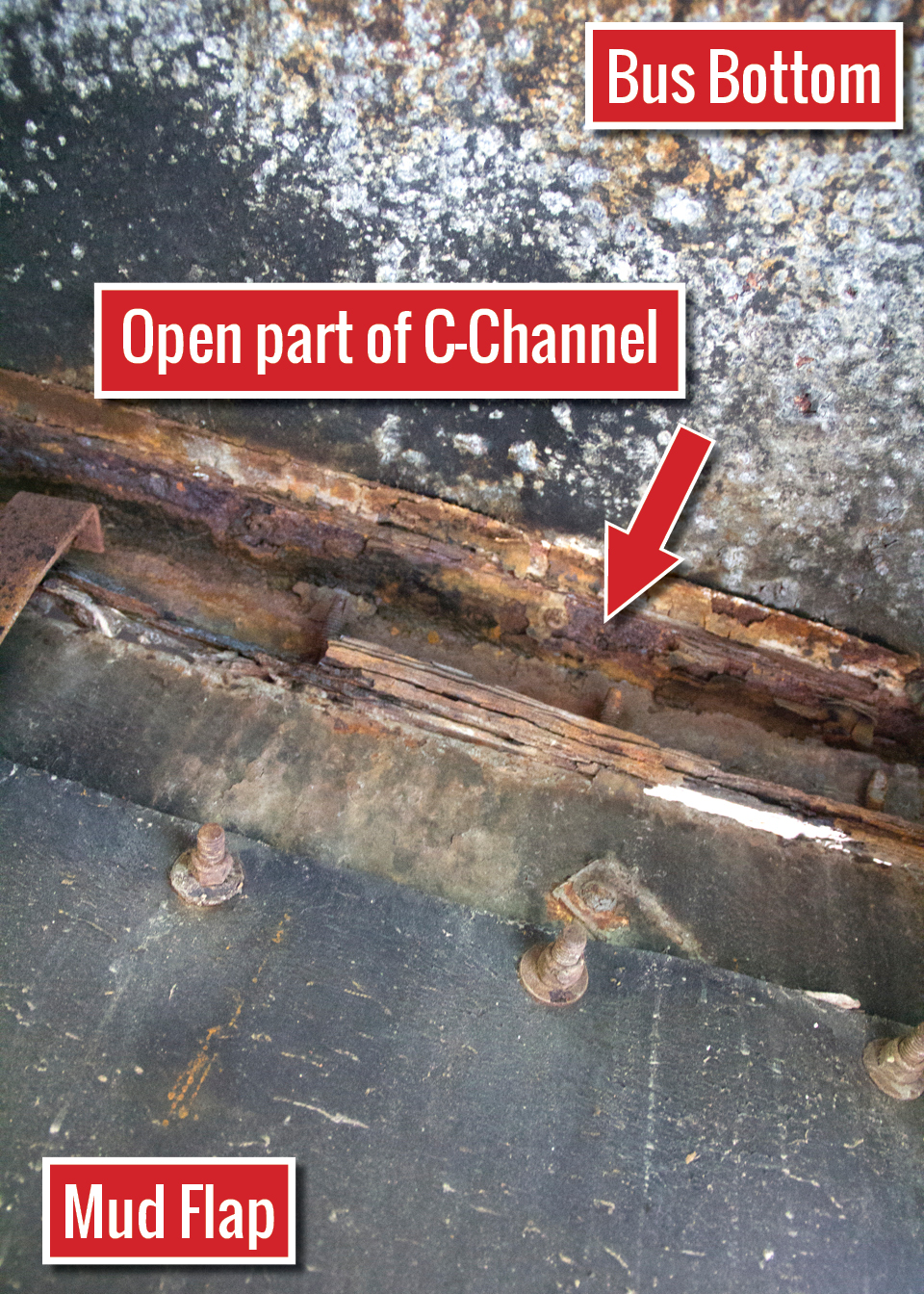

Known as ‘C-Channel’ in the biz, I guess, this beam was just about right in the middle of our bus, right behind the rear dually wheels. I thought about just letting it go and suffering the dippy spot in the interior, but this beam actually was the carrier for the mud flaps as well. In rally, all ‘rear and driven’ wheels must be ‘flapped, and I’m pretty sure that’s a commercial requirement as well. So I couldn’t let it go. Plus, y’know, I didn’t want a pothole inside the bus.

Grinding and scraping our way along, when Steph and I came to the beam, we figured there was not an easy way to replace this thing – and we were right! The good news though, is that just by looking at the placement of the thing, it looked like that when unbolted, the beam would just slide sideways right out the wheel hole, without having to remove all other beams, lift the body off the frame, and then slip it out that way. Grateful to not have to do all of that mess, it was a little tricky getting the thing out into the daylight.

If rusty, holey metal were cheese, this would be Swiss.

This beam had no less than 8,743 rust-welded nuts and bolts that needed to be unbolted – or otherwise removed – before we could even get to any sort of repair. And to that point, this thing was well beyond repair. Of those 8,743 rusted nuts, exactly one came out using traditional removal methods, with two ratchets and two sockets, a gallon and a half of PB Blaster, and one of us in the bus and the other under the bus, which has become my second home.

The rest of those confounded bolts came out one at an ear-shrieking time with an industrial strength 4.5-inch Metabo angle grinder gifted to me by my friend Bill Doyle, who built my roll cage, suspension, skid plate, and other metal bits for my rally car. Bill is a real metal sorcerer and lightning tamer by trade. But a few of my least favorite things are loud noises, unholy machines, and sparks near gas tanks. This particular job contained all three – and the need to be back in the HAZ-MAT under a dark bus. Fabulous.

The only thing holding up this mud flap is hope.

The morning’s grinding turned into afternoon’s grinding while Steph was wire-brushing more Titanic off the bottom of the bus. Those who know me know that I could pass for a Sasquatch’s second cousin, while Steph could pass for pixie. I got to a point where all the bolts had become rusty shafts of pain and hot metal on the driveway – except for that one. That one bolt that hides. Moves somehow. Buries itself in more rust, cackling, like a Gremlin after midnight with a mozzarella stick in its hand. I could only reach it with one hand on the grinder and anyone who knows grinding knows that’s the quickest way to the ER yo get your limbs sewn back on, y’know, if you still have eyes left to dial 911.

The sprite though, well, she was a different story. While I had to squirm, wiggle, inch-worm, and scrape under the bus, Steph could sit upright with enough room for a top-hat fresh from the Mad Hatter. She asked me how to use the whirling menace and off she went. The first chunk of beam came out as a twisted piece of rusted metal sharper than a Ginsu (I’ll have that bronzed later). Then before I knew it, that last bolt shot out, ricocheted off the frame, and landed, smoking in the driveway. We looked at each other suddenly, as the grinder wound down to silence. We were still swathed in protective face shields, goggles, fogged glasses and the like, and smiled and high-fived like a couple school playground kickball champions.

We did it.

The beam was now loose from its crusted confines, sitting on the diff and heavy-duty springs. I scraped, inch-wormed, wiggled, and squirmed my way back out from under the bus. Steph walked out from underneath and waited for me for some more high-fives, this time, in the maskless fresh air of success. The summer breeze cooled our rust complexions as we exhaled in sweet relief.

Those bolts were supposed to just slide right out. Yep. Sure they did.

After a guzzle of ice-cold water, we stripped our Hazzies off, re-gloved, and began Tetris-ing out the beam. We turned, twisted, clunked, and shifted it out from under the bus like Jiminy Cricket trying to pick a human-sized lock. Instead of our conscience being our guide, it was more like blind faith, because neither of us knew if it was actually just going to come out at all. After a few minutes of clinking and clanking though, we had extracted the thing all the way out into the waning light of summer.

No need to take our iron pills that day, as we had swallowed enough rust to set off any airport metal detector. I traded in the Metabo for a bottle opener and splashed open a fresh brew in celebration for a long Saturday’s work.

Next Up: The beam came out. Now what’s going in?

Steph the Conquerer: After a 3-second walk-thru with the grinder, Steph came out in her Hazzies victorious against the rust-welded bolts. Below, the last bolt location.